INJECT-STYRENE TECHNOLOGY

Technical data: Écobill MD/®

TECHNICAL DATA SHEET: Écobill MD/®

ECOBILL MD/® DATA SHEET

Product description

Ecobill MD/® insulation is made from a blend of certified graphite polystyrene and recycled polystyrene microbeads, injected with a water-based acrylic binder into an existing or new space. In-situ contact point agglomeration technology. The agglomerate dries and sets in a few days. This insulation product exceeds the requirements of the CAN/ULC S701.01.2017 (including amendments) Quality Standard for Factory-Built Board Rigid Polystyrene Insulation.

| REFERENCE STANDARD | CAN/ULC S701.01.2017 |

| CLASSIFICATION (REF.) | Type 1 |

| COMPOSITION | EPS-25% recycled microbeads, 98% air and 2% plastic |

| ACRYLIC BINDER | Not GHS classified, not self-flammable |

| COLOR | Greyish and/or white |

| BEAD SIZE | 1 to 3 mm |

| STRUCTURE | Micro-cellular / non-hydrophilic |

| DENSITY | 12kg/m3 to 21kg/m3 |

| DIMENSIONAL STABILITY | No swelling or shrinkage. Stable at 98.9%. |

| COMPATIBILITY | All wood, plastic, steel, concrete, plaster and other materials |

| FLAMMABILITY | Contains a flame retardant |

| OPERATING TEMPERATURE (MAX.) | 75 C |

| SELF-IGNITION | 400-500 C |

| NON-CAPILLARITY | Does not retain water |

| HEALTH HAZARD | None known. Dust- and vapour-free |

| VERMINE | Does not encourage vermin |

| MOISISSURE | Does not contribute to mold proliferation |

Technical data

Testing and standardization carried out by independent laboratories recognized by the Canadian Construction Materials Centre (CCMC): UL/CLEB, Intertek, Sagéos

| TECHNICAL DATA | METHOD | RESULT |

| THERMAL RESISTANCE | ASTM C518-10 | R- 4.3 /in |

| WATER ABSORPTION | ASTM D2842-12 | 0,6 % |

| WATER VAPOUR PERMEANCE | ASTM E96-00 | 1980 ng/Pa/s/m2 34.6 perms |

| AIRBARRIER | ASTM E2178 / AS01210-A | 75 Pa / +49 L/s-m2 |

| DENSITY | 18kg/m3 | |

| MOISISSURES | ASTM C1338-2014 | Pass |

| VOCS | CDPH01350 – v 1.1 | Class-room / Pass |

| COMPRESSIVE STRENGTH AT 10% DEFORMATION (MIN.) | ASTM-D-1621 | 5 psi |

MICROBEAD INJECTION

Sequence of work

The Inject-Styrene process stands out for its simplicity, originality and technical features, its energy efficiency comparable to the best insulating materials on the market, and its superior ecological and environmental performance.

Discover the sequence of works for the injection of recycled microbeads.

Preparing for injection

25 mm diameter holes are drilled in your wall or partition to inject the polystyrene insulation.

Insulation injection

Recycled polystyrene microbeads are injected into the wall or partition, insulating it without demolition.

Closing after injection

Wood or plaster, the wall can be resealed immediately after injection. This makes it possible to achieve complete, effective insulation in a short space of time, without having to demolish the walls.

An ecological and economical solution.

Finalizing the work

Older buildings generally lack an effective vapour barrier to combat moisture migration inside the walls.

This moisture migration, which is bound to cause a great deal of damage over time, can be stopped by applying a vapour-barrier paint. A simple and highly effective method, when applied as recommended. Ask your professional for more information.

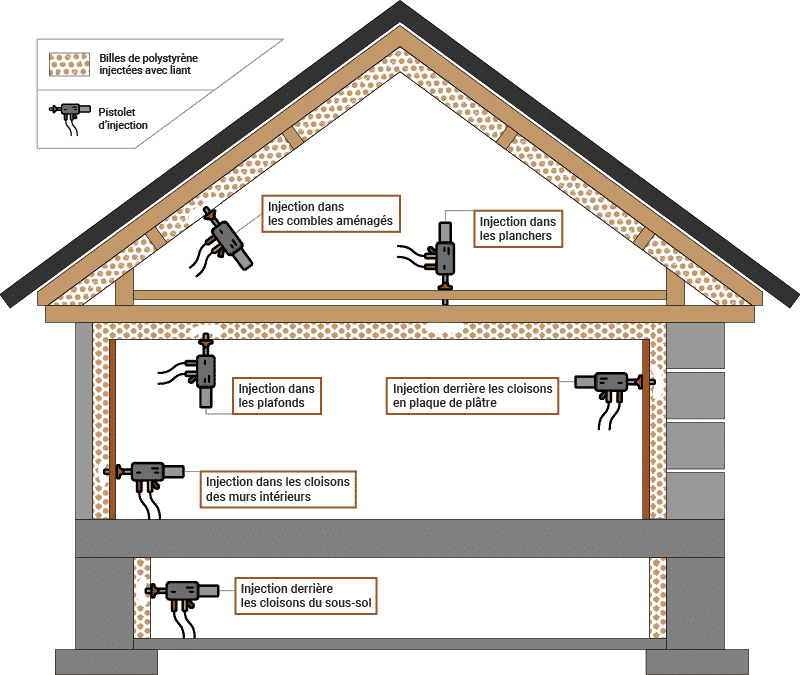

BUILDING APPLICATIONS

Injection options

Ecobill MD/® insulation is produced by injecting agglomerated polystyrene microbeads to fill air gaps of 1 inch (2.5 cm) minimum and 16 inches (40 cm) maximum. In addition to its high thermal value, Injected Microbead Insulation provides excellent control over air movement.

-

- Interior wall

- Cathedral roof

- Floor, Ceiling

- Edge joist

- Interior foundation wall

Advantages and benefits

- No demobilization of the occupants.

- Protect the built heritage.

- Easy, fast, clean and low-cost installation.

- No construction waste or harmful dust.

- Inject behind cabinets and sanitary equipment

- High thermal value

- Stable, permanent insulating value

- Unsurpassed injection efficiency in air gaps between 1′ and 4′ inches thick (2.5 cm to 10 cm)

- The injection process involves no risk of pressurizing the partitions.

- Polystyrene microbeads encapsulate and conform to any shape in the partition. As a result, it fills voids completely (even in 2-3 mm wall gaps).

- Eliminates convection and air movement in walls. This increases the building’s energy efficiency while reducing energy consumption.

- Improved occupant comfort.

- Stable over time, the agglomerate is not subject to settling or shrinkage.

- Non-hydrophilic, air- and water-permeable, prevents water accumulation and limits condensation and humidity problems.

- And it’s harmless to your health.

Limit of use

- Expanded polystyrene microbeads should be considered flammable when exposed to a source of intense heat. Expanded polystyrene must therefore be covered as recommended in the national building code.

- Filling can only take place in voids consisting of two rigid walls. Adheres, but does not stick to surfaces.

- Must not be used in the presence of other granular or fibrous insulating materials that could be mixed with and contaminate or alter the polystyrene insulation, such as sawdust, mineral wool, cellulose, vermiculite, as well as any other petroleum-based solvent products and their emanations that could affect the composition of the insulation.

- Insulation must not be subjected to pressure. Crumbly to the touch.

- Must not be exposed to direct sunlight, inclement weather or heat sources over 90C.

- Not to be used in the presence of water, moisture or mould, or on materials showing major deterioration.

- Does not replace a vapour-barrier system. Use a liquid vapour-barrier coating on the walls before painting.

Ecobill MD/® environmental data

- Product classified as non-hazardous under the Globally Harmonized System (GHS).

- Contains no ozone-depleting HCFCs or HFCs.

- No harmful dust or fumes. Rated A+ by Véritas International for air quality.

- Can be injected into walls without demolition. Contributes to reducing GHG emissions due to the energy inefficiency of old, uninsulated buildings.

- Contributes to reducing the transportation of many construction materials and waste.

- In addition to eliminating landfill or processing of unusable materials.

- At the end of their useful life, injected polystyrene microbeads can be recovered and reused up to 2 times within the same injection process, without altering its effectiveness.

- EPS expanded polystyrene microbeads require almost 3 times less energy to produce than a factory-made rigid panel.

- Contains a minimum of 25% recycled material.

- Recycled polystyrene microbeads come from a positive sorting recovery program within a circular economy concept. Where the consumer/waste producer contributes to the recovery of post-consumer polystyrene through sorting at source.

- The microbeads are mechanically conditioned, without the use of chemicals.

- Does not contaminate contact materials that can be reclaimed.

Warranty

Ecobill MD/® injection-moulded insulation meets the following standards and requirements: CAN/ULC-S701 (including modification)

Opinions

The data and information contained in this document are presented in good faith and based on sources believed to be reliable. This document contains no representations or warranties, express or implied, as to the information, data and suggestions. Since provincial and municipal regulations may vary, and conditions of use may change over time and from place to place, it is the user’s responsibility to determine whether polystyrene microbead injection is suitable for the recommended use in the workplace and in accordance with current standards and regulations.